In my enthusiasm to get the project moving ahead, during the early part of the Baja Bug project, I had cut off too much of the front end sheet metal and had to weld a one-foot section back on in order to have a way to secure the gas tank. When I bought the gas tank from my parts people, there were a variety of tanks available which all looked very similar. We selected one that looked like it would fit and I loaded it up, took it home and stored it in the basement until I was ready to install it. The one thing I didn’t know about that particular gas tank was that instead of having the normal ten gallon capacity, this one held only eight gallons. When I was installing it, the capacity didn’t really matter. Later, it would become somewhat of a problem until I realized what I was dealing with.

One of the disasters I tried to avoid with the Baja Bug project was the Fuel Line Disaster that happened during the Dune Buggy project. The Dune Buggy was built on a 1957 pan, whereas the Baja Bug is a 1967 car. When I hooked up the fuel lines on either end of the steel line that passes through the length of the pan on the Dune Buggy, I had no indication as to the condition of that steel fuel line, since it is hidden inside the center spine of the pan for much of its length. The first time I had any clue as to its condition was when I poured a couple of gallons of gasoline into the tank when I was ready to try to start up the engine. All the fuel I poured into the tank ran out of all the little holes in the steel fuel line inside the spine, eventually running out at each end of the car all over the garage floor. It was a mess and a potentially very dangerous mess, as well. I cleaned up as best as I could and waited a few days for all the fuel to dry up before I fixed the problem. After some evaluation of the situation, I decided to run a whole new metal fuel line through the inside of the car rather than try to replace the hidden line. I used malleable copper for the new fuel line and it has proven to be quite a good solution to the problem.

Given my previous experience with VW fuel lines, I was very careful when I hooked up the Baja Bug lines. To avoid another major fuel spill, I added a very small amount of gasoline to the tank until I was sure all my fuel lines were intact. It turned out that the steel line in the Baja Bug was in good condition, so the installation went very well. I hooked up all fuel lines, dropped in the tank, and tested the system. Everything seemed to be working. Of course, as with all my VW projects “seemed to be” was the key phrase for this one, too. The other component of the fuel system, the fuel pump, also wound up being a problem. The cause was another one of those little tiny, seemingly insignificant, details that I had never encountered before. I leaned that the relationship between the fuel pump, its spacer and the pump rod are very critical.

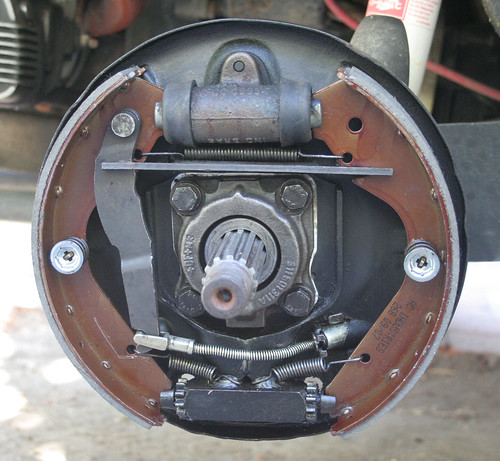

Once I had everything hooked up, it was time for a test drive. After a bit of cranking to get fuel from the tank to the engine via the fuel pump, the engine started up. With a minimum of adjustment, I got the carburetors balanced and the engine idling and drove the car around the block to make sure there were no steering, braking, or shifting problems. All systems seemed to be operating perfectly. They weren’t, but, for the moment, everything appeared to be working properly. I drove the car around the block a couple of times to be sure it was going to continue to work and, again, all systems were working. I pulled it back into the driveway and parked it. Then, I looked it over thoroughly to see if there were any obvious leaks or other problems. It looked good. So good, in fact, that I felt confident enough to take it for a ride on the freeway. It ran really well with good acceleration, adequate braking performance and predictable handling characteristics. As I was cruising south on the freeway, just a couple of miles from home, the engine sputtered and died as if it were out of gas. I coasted off onto the shoulder of the road, got out of the car and started checking out the fuel system. It appeared that the rubber line under the fuel tank had gotten kinked, shutting off the fuel flow. I straightened out the line and tried to restart the engine. I cranked the engine until the battery was too low to turn the starter any more. I had no choice at that point but to call roadside assistance and have it towed off of the freeway. They dropped the car and I on the street just a mile or so from my house. I locked the car doors and walked back to my house where I got my truck and a tow bar and went back and picked up the car.

Once I had the car back in my driveway, I began a careful diagnosis of the problem. There was adequate fuel in the tank. The fuel lines were clear back to the engine, but the fuel pump wasn’t pumping any fuel. I figured it was a defective pump, but, when I removed it, I found that it was actually a broken fuel pump. This is when I leaned about the relationship between the fuel pump, its spacer and the pump rod. If the spacer is too short, the rod pushes up too far and breaks the actuating lever inside the fuel pump. I had another fuel pump on hand and a different spacer. Once I installed the correct spacer, the fuel pump worked perfectly, and I was back on the road.

As I drove the car around town, I kept track of the fuel I was using so I could get an idea of the gas mileage I was getting. This was important because I hadn’t yet installed a fuel gauge on the vehicle. Once I knew how many miles per gallon I was getting, I could figure out how often I needed to fill the gas tank. Not yet knowing that the fuel tank held only eight gallons, all my calculations were based on a tank holding ten. I usually fill up the gas tanks on my VWs every one hundred miles, so having a tank that held only eight gallons didn’t become evident until I got lazy one day and made a trip under the assumption that I had plenty of gas left in my tank to make it to the gas station. That would have been true if the tank had held ten gallons. Since it didn’t, I ran out of gas on the freeway. Being as it was the weekend when this occurred, the freeway rescue trucks weren’t running, so I had to call my wife. She was at my brother-in-law’s house and she sent him to rescue me. He brought me a gallon can which I emptied into the tank. When I got to the gas station, it took seven and a half gallons of gas to fill that tank. That was when I discovered the real capacity of that tank. I haven’t run out of gas in that car since.

The gas tank in the Baja Bug is the only eight gallon VW gas tank that anyone has ever heard of. I’ve never bothered to replace it with a ten gallon tank. I just know that I can’t get lazy and go much beyond one hundred miles before I fill up the tank. I will leave you with this bit of advice, though: If you are going to run your VW without a fuel gauge, be sure to check the capacity of the fuel tank before taking any long trips, or carry a gallon can of fuel in the trunk, just in case.